Recycled Polyester vs Polyester: 5 Shocking Differences

April 6, 2024

Cool Winter vs Cool Summer: How to Tell The Difference

April 11, 2024Choosing the right fabric can feel overwhelming when labels list unfamiliar terms that all seem to mean the same thing. From durability to breathability, synthetic materials vary more than we often realize. In this guide, you’ll find a clear overview of popular and lesser-known synthetic fabrics and the characteristics that set them apart. Let’s dive in!

A Comprehensive List of Synthetic Fabrics

- Polyester

- Spandex

- Vinyon

- Saran

- Olefin

- Modacrylic

- PBI (Polybenzimidazole fiber)

- M-5 (PIPD fiber)

- Orlon

- Polyurethane (PU)

- Elastane (EL/EA)

- Chlorofibers (from PVC)

- Aramids (Nomex, Kevlar, Twaron)

- Fluorofibers (GORE-TEX)

- PLA (Polylactic Acid)

- Sulfar

- Acrylonitrile

- Cupro

- Trevira

- Acrylate

- Nylon

- Acrylic

- Lycra

- Microfiber

- Acetate

- Rayon (semi-synthetic)

- Carbon Fiber

- Dyneema

- Technora

- Vectran

- Spectra

- Teflon-coated fabrics

1. Nylon

DuPont introduced nylon, a synthetic polymer fiber, in 1938 as strong, durable, flexible nylon stockings. This completely synthetic material derives from petrochemical monomers like hexamethylenediamine, produced from crude oil.

A non-biodegradable plastic, nylon persists in the environment for centuries and generates effluents with toxic substances if not properly treated during production. Its wastewater discharges can pollute aquatic ecosystems, while air emissions include nitrous oxide, a greenhouse gas 310 times more potent than CO2

Key traits of nylon are the following:

- Versatile, silky plastic made from petroleum

- Can be melted into fibers, films, shapes for various uses

- Highly elastic, retains shape when stretched

- Used in apparel, flooring, rubber reinforcement, molded parts

- High crystallinity from regular backbone enhances fiber properties

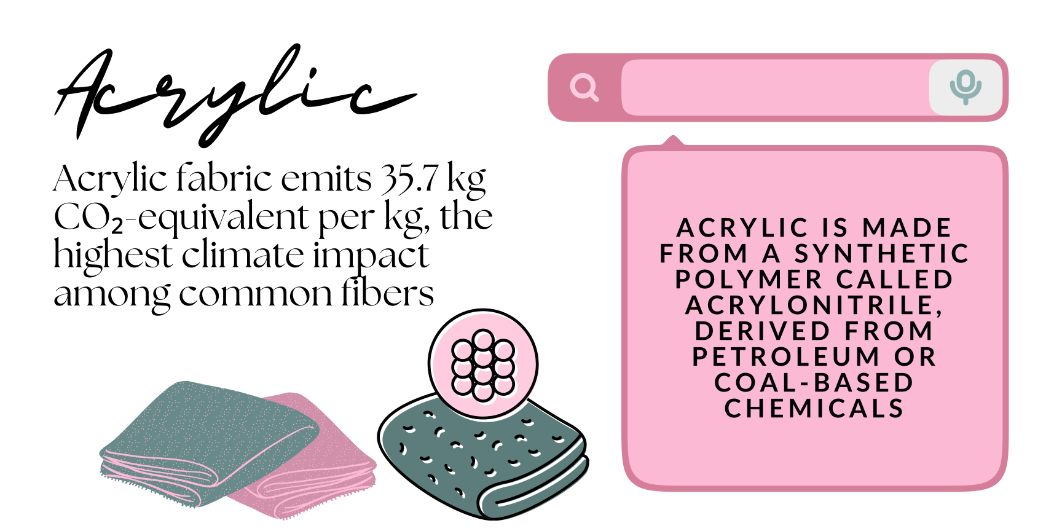

2. Acrylic

Germany first manufactured acrylic in 1893, exhibiting wool-like characteristics and properties. DuPont introduced it to the U.S. market in 1950. By 1991, manufacturers widely used acrylic for sweaters, blankets, and other wash-and-wear items.

A synthetic fossil fuel derivative of petroleum and coal chemicals, acrylic does not biodegrade. Its energy-intensive production releases harmful gases, toxic substances, and microplastics into the environment. Like other synthetic fibres, acrylic fabric degrades slowly, taking up to 200 years and contributing to plastic pollution.

Key traits of acrylic include:

- At least 85% acrylonitrile, a fossil fuel-based fiber

- Low breathability for heat retention in athletics/clothing

- Soft, fluffy, curly fibers resembling wool

- Poor moisture absorption, low abrasion resistance among synthetics

- Can be blended with wool-type fibers, viscose, or polyester

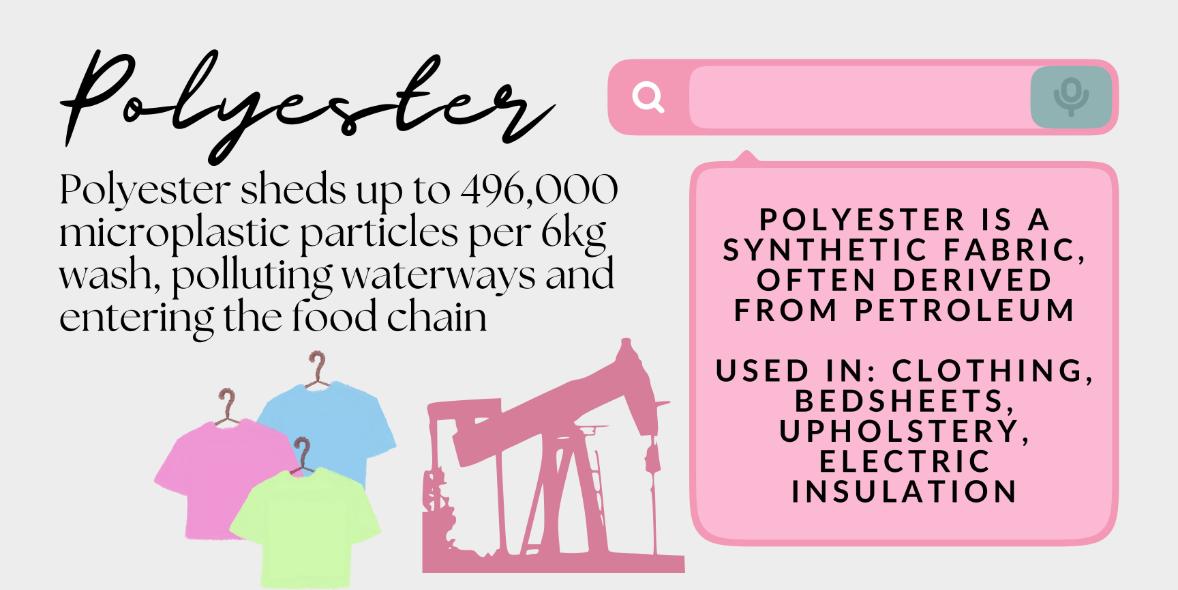

3. Polyester

Polyester, a synthetic fiber derived from oil, accounted for 52% of globally produced fibers in 2020. While light, strong, easily dyed, and versatile for weaving or knitting, its petroleum-based origins and manufacturing processes significantly impact the environment.

Polyester’s energy-intensive production emits harmful air pollutants. The fabric takes up to 200 years to biodegrade, and when washed, it sheds microfibers that pollute oceans and drinking water worldwide. This makes it the most notorious choice in the list of synthetic fabrics in terms of its negative environmental impact.

Here are some of the main properties of polyester:

- Remarkably elastic, retains shape when stretched

- Highly resistant to environmental conditions for outdoor use

- Versatile uses in clothing, bedding, upholstery, industrial products

- Often blended with cotton for improved durability, shrink/wrinkle resistance

4. Spandex (Also Known As Elastane)

Spandex/elastane/Lycra is a synthetic polyurethane fabric that can stretch up to 600% then revert to its original size. Derived from petroleum, a non-renewable resource, its production utilizes toxic chemicals like carcinogenic TDI and MDI, harming the environment and potentially the health of garment workers.

Spandex clothing can trigger allergic reactions from chemical dyes and formaldehyde, causing fungal/bacterial skin infections like ringworm due to moisture buildup. It can also increase the risk of yeast infection in warm conditions by restricting breathability.

Key properties of spandex include:

- Often blended with other fibers, such as cotton, polyester, or nylon, to add stretch and comfort.

- Used in athletic wear, swimwear, jeans, lingerie

- Toxic on skin, causing dermatitis and other skin irritations, and may contain latex, which can cause allergic reactions.

- Contains carcinogenic and mutagenic substances, such as polyurethane and TDI

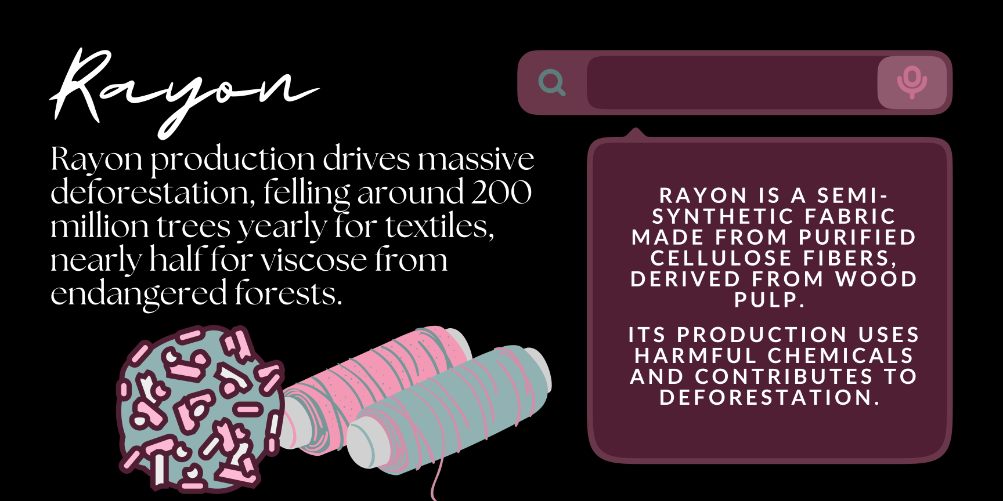

5. Rayon (Also Known As Viscose)

Invented in the late 1800s as an artificial silk alternative, rayon is a regenerated cellulose fiber made from wood pulp or cotton plant materials. Due to its origins, the fabric is considered semi-synthetic, however, this does not mean it’s breathable or safe for consumer health.

Transforming from cellulose cast-offs into a fabric, rayon leaves a trail of hazardous compounds. Its production, known as the ‘viscose process’, requires the use of formaldehyde resins, carbon disulfide, and other toxic solvents to mold natural cellulose into fibers.

These solvents can cause neurological damage, reproductive issues, dermatological problems, and even cancer – both in garment workers producing rayon and in end consumers who wear the fabric. This makes rayon a carcinogenic fabric, as it is treated with formaldehyde – which is used to make rayon wrinkle-free – a human carcinogen known to cause leukemia and nasopharyngeal cancer when inhaled or ingested from fabric fibers over time.

Rayon has the following properties:

- Prone to wrinkling, requiring regular ironing or steaming

- Shrinks easily when washed

- Its fibers weaken when wet, making the fabric more vulnerable to damage during washing and drying

- Prone to pilling and fuzzing

- A popular choice for softness, drapability, and color quality

6. Modal

Some might claim that modal is a sustainable fabric due to its biodegradability, as it is a semi-synthetic fabric derived from beech tree pulp. The fabric also consumes far less water than conventional cotton, accounting for only 1/20 of cotton’s water footprint. However, do not let this fool you.

Modal remains a chemically intensive, semi-synthetic fiber, and its production process raises concerns regarding worker safety and environmental impact.

Closed-Loop vs. Conventional Modal

Without a closed-loop recovery system, harmful chemicals in modal production can escape capture during production, leaching into air and water systems and posing threats to wildlife, aquatic ecosystems, and nearby communities.

This is why industry leaders like Lenzing, the manufacturer of TENCEL™ Modal, have invested in closed-loop technologies that recover and reuse the majority of solvent emissions, an essential distinction when evaluating the sustainability of modal.

PRO Tip: Modal can be a lower-impact fabric only when produced using advanced, closed-loop systems. Consumers and brands should look for certified or transparently sourced modal, particularly from suppliers with verified solvent-recovery processes and robust worker-safety protections.

Key properties of modal include:

- Features excellent tensile strength and abrasion resistance, making it suitable for gears, seatbelts, ballistic cloth, machinery parts, and ropes

- Lighter in weight than polyester

- Boasts high elongation and elastic recovery

- Tends to be less flammable, as compared to viscose and cotton

7. Polypropylene

Polypropylene is a staple synthetic for activewear and outdoor apparel. This thermoplastic polymer excels at wicking moisture, dries quickly, and delivers lightweight insulation. Its durable fibers resist water, staining, and rigorous use. Major brands incorporate polypropylene into athletic gear, thermal underwear, swimsuits – that is, anything demanding lasting performance.

However, polypropylene’s practicality carries an environmental toll. Production guzzles non-renewable fossil fuels and belches greenhouse gases. When thrown away into landfills, polypropylene sheds microplastics that pollute ecosystems and harm wildlife.

Here are some of the main properties of polypropylene:

- Features low density and high heat resistance

- Is very flammable, requiring flame-retardants and additives to reduce its flammability

- Versatile material used in packaging, automotive, medical, and consumer goods

- Is lightweight, high-strength, and cost-effective material

- Is waterproof and a great insulator

8. Cupro (Also Known As Ammonia Silk)

Cupro is a man-made fabric derived from cotton waste, specifically the short, downy fibers that stick out of the cottonseed, known as cotton linters. These fibers are too small to be used in the production of cottonseed oil, so they are repurposed to create cupro.

The manufacturing process involves dissolving the cotton linters in a solution of copper and ammonium, known as a cuprammonium solution. This process can be highly toxic, due to the use of caustic soda, which not only poses risks to the environment but also fosters occupational hazards at cupro factories. At disposal, modal generates as much, if not more, toxic waste as synthetic fabrics.

Given that, here’s what you need to know about cupro:

- Often marketed as a more ethical, vegan alternative to silk (which is a form of greenwashing, as organic silk is more environmentally-friendly and non-toxic)

- Praised for its smooth texture, fineness, lightness, and ability to drape like silk

- Involves an energy-intensive production process, particularly, during the purification stages

- Used in high-end apparel, industrial materials, and home textiles

9. Modacrylic

A modified version of traditional acrylic, modacrylic fibers contain 35-85% acrylonitrile by weight. For a comparison, conventional acrylic is composed of at least 85% acrylonitrile. The fabric was created as a modified, flame-resistant version of acrylic – a property useful for chemical-resistant clothing, outerwear, and household furnishing.

The main concern lies in its key ingredient, acrylonitrile. Workers who help produce or process this chemical may face health risks if factories lack proper protection. Exposure has been linked to symptoms like headaches, breathing irritation, and fatigue.

Since acrylonitrile is classified as a probable human carcinogen, robust ventilation, protective equipment, and strict oversight are critical. Yet in many parts of the fashion supply chain, these safeguards are limited or inconsistently enforced, leaving workers most vulnerable to its effects.

10. Olefin

Olefin is a man-made fiber created from plastic materials like polypropylene or polyethylene. Its production involves combining ethylene gases and adding color to the polymer before melt spinning it into thin threads.

These olefin fibers are strong, resist fading, staining, mildew, abrasion, and sunlight. They also feel comfortable and can absorb some moisture while drying quickly. All of these advantages, however, come at an environmental cost. Olefin is made from petroleum, a non-renewable resource, and it leaches toxic substances into water, air, and soil.

Here are the main properties of Olefin:

- Doesn’t easily get static cling and is difficult to melt

- Widely used for activewear and socks, car interiors, furniture upholstery, and curtains.

- Isn’t easily dyed, but is colorfast

- Features resistance to staining, mildew, and abrasion

11. Microfiber

Microfiber fabric combines ultra-fine fibers of polyester and nylon, making the fibers much thinner than human hair. This construction allows microfiber to absorb liquids and trap dust and dirt extremely effectively. Initially, microfiber cloths gained popularity for their efficiency in cleaning without chemicals. However, today, concerns arise about its environmental impact.

During production, manufacturers craft microfiber from non-renewable, petroleum-based resources that do not biodegrade. What’s more, the fabric sheds tiny microplastic fibers that pollute water bodies, harming marine life and entering the human food chain.

Here’s what you need to know about microfiber:

- Used in cleaning textiles, as it reduces bacteria on surfaces better than cotton.

- Features ultra-fine fibers that are thinner than human hair

- Highly absorbent, lint-free, soft, and durable

12. Fleece

Fleece is a soft, lightweight, and insulating synthetic fabric made from polyethylene terephthalate (PET) or other man-made fibers. Malden Mills, now known as Polartec, first introduced fleece in the 1980s through a collaboration with Patagonia’s founder Yvon Chouinard. The fabric’s ability to wick away moisture, its light feel, and easy care make it popular among outdoor enthusiasts and casual wearers alike.

Manufacturers produce fleece by melting non-renewable petroleum derivatives and weaving them into thin filament threads, creating a tightly knit fabric. They then brush the fabric to create its signature bulky texture.

PFAS in Fleece Undermine Worker Safety

For garment workers, the risks are most present during the manufacturing and finishing stages. Facilities that apply water- or wind-resistant finishes may use fluorochemicals, including PFAS-based treatments. Without proper ventilation, protective equipment, and wastewater management, workers may face high exposures, especially in regions with limited factory oversight or weak environmental regulation.

Key properties of fleece include:

- Offers excellent insulation without the weight and bulk associated with other materials

- Features a cozy and plush texture

- Machine-washable and wrinkle-resistant

- Comes in various weights, textures, and styles and dries faster than some synthetics

- Susceptible to static cling

- Develops pilling quickly, where small balls of fiber appear on the fabric surface

13. Vinyon

Vinyon is a synthetic fiber made from polyvinyl chloride (PVC) that manufacturers first invented in 1939. Initially, the fabric served as a substitute for plant-based filters in tea bags, but its use has declined due to the health concerns around PVC and vinyl chloride.

Manufacturers produce vinyon using vinyl chloride, which the International Agency for Research on Cancer classifies as a Group 1 carcinogen. Exposure to this compound can lead to an increased risk of liver cancer, brain cancer, and lung cancer.

Key properties of vinyon are the following:

- Known for being non-flammable, vinyon is highly resistant to chemicals and has low moisture absorption

- Suitable for industrial applications as a bonding agent for non-woven fabrics and products

- Features low moisture absorbption, which can lead to mildew

- Can release hydrochloric acid when heated

- Used in outdoor gear, such as backpacks and raincoats

14. Chlorofibers

Chlorofibers, also referred to as chlorofibre, is a lesser known fabric in our list of synthetic fabrics. They represent a type of synthetic fibers that derive from polyvinyl chloride (PVC), which comes from salt and petrochemicals.

To make chlorofibers, manufacturers dissolve certain chemicals in a solvent mixture and spin the PVC solution into fibers. They can make different types by stretching the fibers varying amounts as they exit the spinning nozzle. Chlorofibers don’t absorb much water, get soft at around 70°C with shrinkage, and don’t take dye well at moderate temperatures.

The key downside of chlorofiber production is that it emits toxic gases, such as hydrogen chloride (HCl) and carbon monoxide (CO) when burned, which are hazardous to inhale. The disposal of the fabric can also contribute to environmental pollution by releasing harmful chemicals into the air, water, and soil.

Key properties of chlorofibers include:

- Non-flammable, quick-drying, water resistant, and crease resistant

- Features high thermal insulation, electricity, and acoustic insulation

- Suitable for clothing, linens, filter clothes, curtains, and fishing nets due to their excellent resistance to water, fading, and fire

15. Acetate

Acetate fabric is a synthetic material made from cellulose acetate fibers, developed in the early 1900s as an alternative to silk. Manufacturers commonly use it to produce women’s clothing like blouses, dresses, and skirts, as well as linings, ribbons, and lingerie.

The fabric gets its lustrous, silky appearance and lightweight feel through a process called wet spinning. In wet spinning, manufacturers first extract cellulose from wood pulp or cotton linters. Then, they treat it with acetone solvent to craft cellulose acetate.

Exposure to acetone and methylene chloride (another solvent used in acetate production) can be harmful to ingest or inhale, posing occupational hazards among acetate workers.

Key properties of acetate include:

- Boasts a luxurious appearance resembling silk

- Lightweight and airy

- More absorbent than synthetics, less than natural fibers

- Commonly used in gowns, lingerie, wedding dresses, linings, scarves, and ties

- Requires special care to avoid damage from high heat

List of Synthetic Fabrics: Final Thoughts

Fabrics come in many forms, ranging from sustainable, natural options to high-performance synthetics. While some prioritize durability and function, others focus on cost considerations. However, the often overlooked factors remain garment worker well-being and environmental protection, which are areas where synthetic materials fall short.

Frequently Asked Questions

Polyester is strong, quick-drying, wrinkle-resistant, and maintains color well, making it popular for activewear and everyday garments. Cotton is breathable, soft, and absorbent, offering natural comfort for sensitive skin. While polyester excels in durability and moisture control, cotton provides better temperature regulation but may shrink or fade over time.

Polyester, nylon, and spandex are widely used in activewear for their performance benefits. Polyester wicks moisture and dries quickly, nylon provides flexibility and strength, and spandex offers exceptional stretch and shape retention. Together, they support mobility, comfort, and durability during sports, workouts, and high-intensity movement.

Nylon and acrylic originate from petrochemical-based monomers, which undergo polymerization to form long molecular chains. The resulting liquid polymers are then pushed through spinnerets to create filaments, solidified, and spun into yarns. These fibers are processed, textured, and dyed for use in clothing and textiles.

Polyester, nylon, acrylic, and fleece commonly release microplastic fibers during laundry. Friction, warm water, and detergents dislodge tiny filaments that travel through wastewater systems into oceans. Opting for microfiber wash bags, shorter cycles, and lower agitation can reduce shedding and environmental impact.

Locate the care label, typically along the side seam or neckline. It lists fiber content by percentage, such as cotton, polyester, elastane, or blends. The label may also include icons showing washing, bleaching, drying, and ironing instructions to ensure proper garment care and longevity.

Sources

- Blackburn, Richard S. Sustainable Textiles: Life Cycle and Environmental Impact. Woodhead Publishing, 2009.

- Hethorn, Janet, and Connie Ulasewicz, editors. Sustainable Fashion: What’s Next? A Conversation about Issues, Practices, and Possibilities. Fairchild Books, 2018.

- Kadolph, Sara J. Textiles. 12th ed., Pearson, 2016.

- Claudio, Luz. “Waste Couture: Environmental Impact of the Clothing Industry.” Environmental Health Perspectives, vol. 115, no. 9, 2007, pp. A448–A454.

- Fletcher, Kate, and Lynda Grose. Fashion and Sustainability: Design for Change. Laurence King Publishing, 2012.

- Muthu, Subramanian Senthilkannan. Textile Wastewater Treatment: A Critical Review. Springer, 2016.

- Shen, Li, Ernst Worrell, and Martin K. Patel. “Environmental Impact Assessment of Man-Made Cellulose Fibres.” Resources, Conservation and Recycling, vol. 55, no. 2, 2011, pp. 260–274.

- Niinimäki, Kirsi, and Lotta Hassi. “Emerging Design Strategies in Sustainable Production and Consumption of Textiles and Clothing.” Journal of Cleaner Production, vol. 19, no. 16, 2011, pp. 1876–1883.

- Rosato, Dominick V., Donald V. Rosato, and Marlene G. Rosato. Plastics Engineered Product Design. Elsevier, 2003.

- Slater, Kathy. Environmental Impact of Textiles: Production, Processes and Protection. Woodhead Publishing, 2003.