A toxic petrochemical fabric, polyester is the culprit for the global health and textile crises. It takes around 70 to 400 years to decompose the fabric, as it releases harmful chemicals and microplastics into the environment.

To combat the prevalence of polyester, brands have been offering us its recycled counterpart. Yet, did you know that it’s all just an environmental scam? Here’s why.

What is Recycled Polyester?

Known as rPEt (recycled polyethylene terephthalate), recycled polyester is a fabric, extracted from plastic bottles and packaging. Its production involves melting down waste milk, soft drink, and water bottles to create new polyester yarns.

Is Recycled Polyester Eco-Friendly?

Recycled polyester is a greenwashing scam. It may contain more harmful chemicals, such as bleach, antimony, and BPA, than regular polyester, making it dangerous from a safety point of view. Besides, it’s not even recycled from discarded textiles, but rather waste bottles!

1. Recycled polyester is derived from PET bottles

Brands advertise the use of recycled polyester as eco-friendly, portraying it as a way to breathe new life to virgin polyester fabrics. In other words, they misrepresent recycled polyester as a new iteration, secondhand version of polyester textiles. This, however, is far from the truth.

In reality, the origins of recycled polyester have nothing to do with textiles. The fabric actually comes from the food & beverages industry, particularly, recycled Polyethylene Terephthalate (PET) bottles.

Essentially a bottle-derived fabric, recycled polyester is a low-cost, thermoplastic textile. It boasts durability, sturdiness, and resistance to mildew, coming off as a practical yet ethical alternative to polyester.

However, there’s more to the picture. In reality, its popularity is concerning, as it not only fools the consumer but also disrupts the way the bottle industry should operate.

2. Recycled Polyester Undermines the Circularity of the Fashion Industry

It’s no news that fashion has a plastic problem. Around 60% of global PET (plastic) production goes into textiles, spawning the rise of toxic, virgin polyester clothes. The PET bottle industry gets only 30% of the share. So, overall, one of the most frequent end uses for PET comes down to clothes.

Given that, you may wonder, if PET polyester is so rampant in fashion, why don’t we recycle it back into new fabrics indefinitely? In other words, why does rPET (recycled polyester) has to come from PET bottles, rather than PET fabrics (polyester)?

The reason behind this lies in greenwashing. Recycled polyester doesn’t necessary reduce the use of virgin polyester in fashion. Yet, it provides an eco-friendly alibi for brands to continue generating more textile waste – under the pretext of promoting recycling initiatives.

There’s Not Enough rPET Left for The Bottle Industry

In Europe, the bottle industry invests heavily into recycling programs, turning old bottles into new ones and achieving a closed-loop system. However, there’s not enough recyclable waste for them left on the market. With the growing demand for recycled polyester, the fashion industry steals the rPET resources away from the bottle industry itself.

Fashion’s pursuit of rPET intervenes with the bottle industry’s objective to become fully circular. As Tison Keel, an industry expert, mentions, the textile industry’s “bottomless” appetite for rPET is problematic, as it takes up 3/4 of all annual rPET resources.

Fashion May Inflate the Price of rPET Again

In the past few months, the rPET market has become stable, as the price of the material has settled around $1,600 per ton in Europe. Considering past fluctuations and peaks, this price point is quite low, and it’s for a reason.

Currently, the region has imposed stricter regulations on plastic imports & exports, such as the UK plastic packaging tax, which spawned some challenges on the supply front. Plastic waste resources on the market is restricted, which is one of the reasons behind the temporary price drop. However, the future may paint a contrasting picture.

Skyrocketing rPET Costs and Inflated Demand from Fashion

With more and more retailers tapping into the recycled polyester trend, the price of rPET skyrocketed at a certain point in Europe. In Germany, it reached a whopping $2,500 per ton in June, 2022, due to the soaring demand from e-commerce and automotive industries. If such price inflations make a comeback, they may discourage the plastic bottle industry from using rPET altogether.

According to Kahlert & Bening, the EU pledges to use 2.066 million tons of rPET by 2025. With the current demand for the material, this is an impossible target, as it would require a 53% increase in the current yearly recycling growth rate.

Simply put, fashion’s role in the rPET market brings more harm than good. It inflates the price of the material, as brands go beyond their sustainability targets at times.

For instance, Adidas promises to switch to 100% recycled polyester by 2024. Simiarly, H&M pledges to only use recycled textiles by 2030, with an emphasis on rPET. These targets are not only questionable but also potentially harmful for the rPET market.

Recycled PET is becoming as rare and expensive as gold or white truffles

UNESDA Soft Drinks Europe

What’s the solution to it all? Well, rather than packaging rPET as a sustainable option, fashion brands should recycle their own products. Real circularity is about transforming discarded products into something new. A thrown away shirt should become a new shirt – neither the garment, nor its constituent materials, should ever leave this loop.

3. Recycled Polyester May Be Cheaper Than its Virgin Counterpart

Is recycled polyester another greenwashing scheme? The incentive behind its usage in fashion lies in profit, rather than pro-environmentalism. As Jared Paben mentions, “the driver is simply cost.” In fact, recycled polyester is much cheaper to produce, as compared to its virgin counterpart.

As of 2022, the price of virgin polyester textiles has reached $1,436 per ton in China. In comparison, rPET costs stand at $1,150 per ton in the entire Asia-Pacific region (June, 2023). This price difference may indicate that rPET is merely a convenient solution for fashion brands.

Truly, recycled polyester requires mechanical recycling, which is less costly on a large scale. As compared to regular polyester, the production process behind rPET takes up 59% less energy. These factors may mold rPET into a more cost-effective resource in the long run.

4. Recycled Polyester May Be More Toxic Than its Virgin Counterpart

Some might claim that in terms of toxicity, recycled polyester vs polyester stand on the same level. However, the effects of the two fabrics are slightly different. The reason behind this lies in their distinct manufacturing processes, as well as their constituent materials.

Recycled Polyester is Sprayed with Chlorine

To produce recycled polyester, PET bottles are transformed into flakes and later, polyester chips, which vary in color. As the chips get forced out into polyester fibers, they get bleached with chlorine, which allows for a white base to form. The base is later colored with different synthetic dyes, going through the yarn production process.

Considering this process, apart from harmful dyes, recycled polyester contains bleach, making it more harmful than regular polyester.

Antimony Oxide Present in Recycled Polyester

What exactly is antimony trioxide? It’s a key compound used to make PET resin. However, it’s also one of the dangerous chemicals lurking in some of the most common examples of synthetic materials, including polyester, recycled polyester, and microfiber. These materials are everywhere—from the clothes we wear to the packaging we use—but they come with hidden dangers.

Antimony trioxide has been linked to lung cancer risks in lab animals, raising serious concerns. Through polyester production, it leeches into the air and water, especially under high heat. This poses a significant health risk to garment workers, who face daily exposure to these toxic substances in their everyday environment.

When it comes to its health effects, workers who come in contact with antimony report gastrointestinal symptoms, such as nausea, vomiting, abdominal pain, and stomach ulcers. In hot weather, the compound also triggers skin rashes, referred to as “antimony spots.”

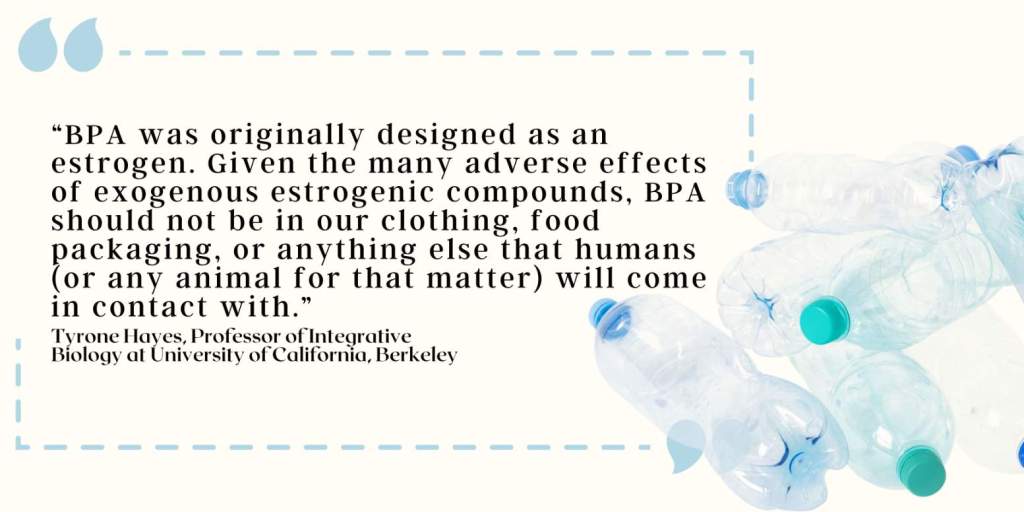

BPA Exposure Through Recycled Polyester

Recycled polyester may contain BPA, which is present in water bottles produced in China. When it comes to the ecosystem, traditional disposal methods of polyester fails to eliminate BPA leakage. Therefore, by producing fabrics from bottles and later releasing them to the landfills, retailers bombard the planet with BPA — a potential xenoestrogen and a cancer-causing agent.

However, BPA exposure isn’t only limited to recycled polyester. Its virgin counterpart is also proven to contain it. In fact, the Center of Environmental Health (CEH) detected the compound in socks, sports bras, and athletic tops made of polyester/spandex. The levels of BPA exceeded the amounts deemed safe by Californian legislation up to 31 times.

Simply put, since the biggest portion of PET comes from Asia, recycled polyester most likely contains BPA. Hence, the main takeaway here is that when comparing recycled polyester vs polyester, the former may contain higher levels of BPA.

5. Recycled Polyester Necessitates Blending with Other Textiles

When created mechanically, the composition of recycled polyester is too weak to form yarns. For this reason, it necessitates merging with other fabrics, such as cotton or bamboo. This poses many challenges in terms of mixed-textile clothing waste. Fabric blends can’t undergo mechanical recycling, making it hard to separate and repurpose them.

However, in recent years, new technology has emerged, which has successfully extracted raw materials out of blended textiles. With water, pressure, and innovative recycling techniques, this technology separates and reclaims natural materials from poly-cotton blends. And if it soon goes mainstream, fabric blends may be no longer result in irreversible waste.

Nevertheless, in the absence of large-scale, special waste management practices, fabric blends still embody the Achilles heel of the industry. For this reason, recycled polyester isn’t a completely clean-handed solution to the clothing waste problem.

Recycled Polyester vs Regular Polyester: Cases of Greenwashing

When shopping for sustainable polyester, you may encounter the label “recycled polyester”, which leads you to assuming that the fabric is entirely recycled. However, unless the label says, “100% recycled polyester”, it’s highly probable that your assumptions will not hold true.

Most of the time, recycled polyester fabrics encompass both virgin and recycled versions of the material. And unfortunately, because of brands’ disingenuous approaches, the former tends to overpower the latter. Here’s why:

Misleading Labels And Certifications

Without third-party verifications, recycled polyester isn’t to be trusted. Firstly, it’s difficult to assess the exact percentage of recycled fabrics present in its composition. Secondly, fabric certifications set the bar too low. For instance, the OEKO-TEX Standard 100 requires that a fabric is only 20% recycled for it to qualify as ‘recycled.’

Varying Recycled Content Percentage

Third-party certifications for polyester are evolving. Perhaps, for the better, as some might claim. For instance, Global Recycled Standard (GRS) has introduced stricter requirements for recycled fabrics, raising the required percentage higher – to 50% minimum – for recycled content of the fabric. By the same token, the Recycled Claim Standard (RCS) applies to products that contain 5% or more recycled content.

While these certifications strive to “provide assurance that materials are actually recycled”, their requirements are too easy for brands to follow. This makes one question whether they’re worth the customer’s trust.

The Bottom Line: Both Recycled And Virgin Polyester Are Toxic

One of the most toxic clothing materials, polyester is a petroleum derivative, meaning it’s a non-renewable, non-biodegradable, toxic resource. When it comes to the environmental harm, polyester emits fibrous microplastics (FMPs) during industrial and household laundry, later spreading into the soil, water, and air. In fact, 35% of FMP emissions come from synthetic textiles – an estimate of 0.47 – 0.49 tons of FMPs annually.

Health Hazards Surrounding Polyester

However, there’s more to the picture. When wearing synthetic textiles, we essentially absorb them – with all their trace particles of dyes, chemicals, and microplastics. To illustrate, polymerization of petroleum involves the use of para-xylene — an industrial solvent — which causes headache, drowsiness, and dizziness upon inhalation. This not only makes us question the occupational hazards of the polyester industry, but also the safety of the fabric itself.

The production of polyester is associated with a myriad of toxic chemicals, such as barium sulphate (a garment finisher), formaldehyde (a resin that gives clothes wrinkle resistant properties), terephthalic acid (used in manufacturing of saturated polyesters), and more.

These chemicals are harmful even in small amounts. Through bioaccumulation, they enter the human body and ultimately, add up. From PFAS to formaldehyde, polyester can harm our health in many unexpected ways.

How Did Recycled PET Start Off?

The post-consumer PET recycling industry emerged as an effort towards waste management. Since the 1950s, 8.3 billion metric tons of plastic have burdened our planet, with only 9% being recycled into new products and 12% being incinerated.

It’s common knowledge that PET is a non-biodegrade polymer with significant physical stability, meaning it takes around 450 years to break down. As no bacteria can consume PET’s large molecules, recycling has always seemed like a logical step towards handling PET waste. In fashion, Patagonia was the first brand to embrace the power of rPET in 1993, as it pioneered the use of recycled polyester through fleece clothing.

Recycled Polyester vs Polyester: Our Final Verdict

To sum up, when comparing recycled polyester vs polyester, we must look at the way brands approach sustainability. Rather than closing the loop since the very inception of a garment, retailers opt for waste from other industries — in order to cover up their wrongdoings. However, waste management isn’t the same as circularity.

Moreover, both virgin and recycled polyester release microplastics and toxic chemicals. Their manufacturing processes are different, however. For instance, recycled polyester require chlorine bleaching to get a uniform color consistency. Polyester, on the other hand, often poses health hazards through various garment finishes, containing azo dyes, formaldehyde, and flame retardants — which could also be present in its recycled counterpart.

The bottom line is, avoid synthetic fabrics when possible and make conscious choices by comparing sustainable fashion vs fast fashion. Bear in mind that our skin is the most porous organ of the body, and it readily absorbs the textiles it encounters. Consequently, by embracing sustainable fashion, which employs non-toxic, natural materials, you will not only contribute to environmental preservation but also your personal well-being.

Ultimately, by rejecting textiles that went through chemical-intensive manufacturing, you will safeguard yourself from a multitude of health hazards, thereby, paving the way for a more responsible and ethical fashion industry for all.